Production process

PRODUCTION PROCESS

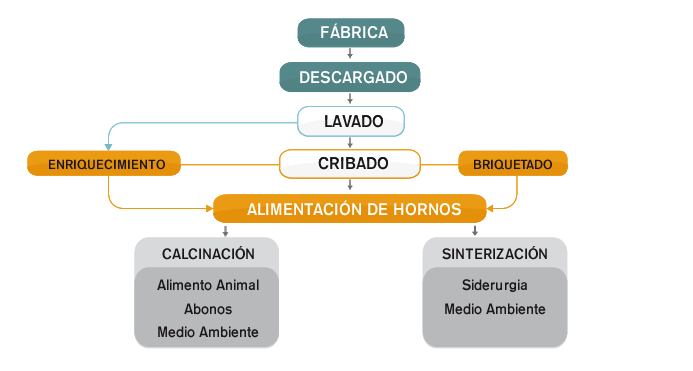

The complex mining and industrial process comprises three main stages, to produce two grades of Magnesium Oxide:

- Stage I: Extraction of the useful material, which is taken to the factory at Zubiri.

- Stage II: Enrichment of the Magnesium Carbonate.

- Stage III: Calcination and/or sintering of the Magnesium Carbonate and dolomite in order to obtain Magnesium Oxide.

Depending on the heat treatment applied to the Magnesium Carbonate or dolomite, and the different areas of application, the following are obtained:

- Sintered or Dead Burned Magnesite (DBM). Processed at more than 1800ºC. Essential in the Steel sector as a refractory. Also termed Sintered Magnesite or Magnesite Sinter.

- Caustic Calcinated Magnesite (CCM). Processed at around 1300ºC. This produces reactive Magnesium Oxide, used in agriculture, livestock farming, the environment and other industrial and chemical technologies.