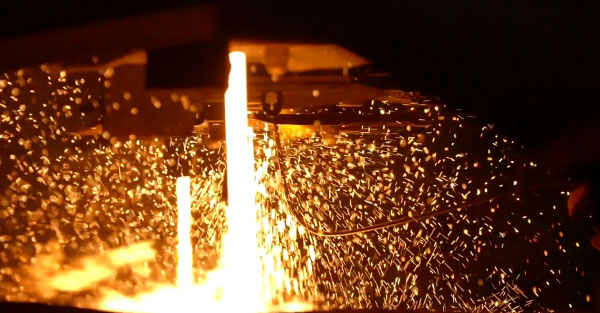

STEELMAKING

STEELMAKING

MAGNA has become an important player on the world refractories market. The company produces refractory masses of MgO for the steelmaking sector and supplies its customers with the machinery required for its application.

We are a totally independent supplier and, therefore, an excellent alternative for our customers, offering them all the advantages of being a vertically integrated company.

Magnesitas Navarras produces refractory masses of different properties for steelmaking:

BOTTOM RAMMING

MAGNA specialises in masses for furnace linings (new furnace bottoms and hot and cold repairs).

We would like to present “MAGSOLUTION”, an exclusive range of turnkey refractory solutions.

- Product: bottom rammings and MgO hot repair material.

- Brands: MAGSOL & AGLUMAG.

- Service: our extensive experience allows us to provide support and advice to our customers.

MAGSOL & AGLUMAG:

- Raw material from our own mine: vertically integrated production.

- Naturally adapted chemical composition (caO / SiO ratio, Iron content, high-density sintered layer, extremely low porosity).

MAGSOLUTION highlights:

- Higher casting rate.

- Shorter repair time.

- Excellent quality-price ratio.

- Lower specific cost.

- Guaranteed safety.

GUNNING

MAGNA is successfully promoting its range of gunning products for EAF, ladles and BOF converters, including the application machinery. Up to now, MAGNA has installed 14 gunning robots (one with a laser measuring system) in 7 countries from Europe, North America and South America, 6 mobile gunning shooters, as well as a large number of common application machines (gunning vessels, spreaders and spinners).

We would like to present “MAGSOLUTION“, an exclusive range of turnkey refractory solutions.

- MgO Gunning Products.

- Application machines (gunners, shooters or robots).

- Servicing, advice and maintenance of our machines.

Competitive advantages:

- Optimal chemical composition.

- The integrated manufacturing process is a guarantee of quality.

- Composition of new ad hoc formulas.

- Access to the complete furnace circumference, including those normally difficult-to-access areas (behind the door).

- Shorter gunning times and frequency.

- Enhanced occupational safety.

MAGSOLUTION highlights:

- Safety.

- Increased refractory life.

- Higher productivity.

TUNDISH

With regard to the tundish products, MAGNA manufactures a range of tundish spraying masses and tundish dry vibe materials.

Furthermore, since 2009, MAGNA has been successfully marketing its dry, cold-setting tundish masses under the COLDMAG brand.

- Tundish product: Coldmag (dry, cold-setting), based on MgO.

- Application: we make the machine available to you.

- Service: we will give you advice and guidance as to the advantages of the system.

- We guarantee a maintenance service.

- Training of your technicians.

Ventajas competitivas del producto

- Energy savings as no drying is required.

- Less risk of inclusions.

- Greater number of sequences per tundish application.

- Fast, efficient and clean application.

In addition to these advantages, it should be highlighted that this material can be pre-heated if required by the manufacturing process and the quality of the steel produced.

This product line was launched in 2009 and has grown quickly, thanks to all the advantages offered. MAGNA currently has 40 customers around the world using this technology, which has become a great commercial success.